Colour & Shape Analysis - IRIS Electronic Eye

With the electronic visual analyzer, characterize the visual aspect of your products. Shapes analysis, colours analysis: this easy and fast-to-use tool allows you to get reliable, objective and detailed measurements. Precious data to produce a positive perception of the visual quality among consumers, also useful for product development.

IRIS,

high resolution imaging visual analyzer

IRIS electronic visual analyzer measures the colour and shape of products in a single analysis, and as they are perceived by the consumer. Thanks to its high measurement accuracy and its analysis reliability in the long term, control the visual aspect of your products to better satisfy your customers.

Unique benefits of IRIS electronic visual analyzer

Unique benefits of IRIS electronic visual analyzer

Using an electronic visual analyzer to evaluate colours and shapes allows our customers to:

- Make sensory evaluation more reliable within their company thanks to an objective and reproducible measurement

- Improve sensory quality of their production and assure its consistency over time by assuring the traceability of products

- Standardize the visual quality of products among production sites on a global scale

- Control the visual features and the aspect of their products thanks to an in-depth knowledge of colour and shape attributes.

IRIS : unsurpassed technical performance

Using high resolution imaging under controlled lighting and imaging conditions, this instrument designed for colours and shapes analysis features unique technical characteristics to achieve unsurpassed performance:

- Simultaneous analysis of colours and shapes as perceived by the consumer: from a single picture taken with a high resolution camera, the electronic visual analyzer assesses the overall product and measures all colours and shape attributes (dimensions, circularity, etc) on the product surface.

- Simplicity and high analysis throughput: the use of the visual analyzer requires no sample preparation and allows evaluating large samples or several samples simultaneously, complex or irregular surfaces, in a non-destructive analysis. Moreover, the analysis can be conducted on the overall product or on selected portions.

- Objectivity and precision for colors and shapes measurement: the use of an instrument like the electronic eye to evaluate the visual aspect in controlled conditions and with high sensitivity to colour differences, even slight ones, guarantees repeatable, reproducible and totally objective results.

- Great stability of measurement of colours and shapes in the long term: thanks to a high repeatability of analysis and from measurements history, the visual analyzer allows to track visual attributes in the long term to guarantee a consistent visual quality over time and assure production batches traceability.

- Qualitative and quantitative analysis capabilities: the data processing software of colour and shape data allows to evaluate both the global appearance of products and also to quantify particular visual attributes.

Thanks to a high reliability of colours and shapes measurements, IRIS visual analyzer can thus substitute to a sensory panel for some routine tests or for in-depth evaluations during product development stage.

Request Brochure

IRIS Smart Vision,

Visual Inspection of Production Batches

Combining high resolution camera imaging and controlled lighting conditions in a closed cabinet, IRIS achieves reliable visual inspection of your products.

IRIS Smart Vision is dedicated to quality control applications involving color or shape measurements.

Also compatible with Alphasoft Advanced Statistics, the IRIS Smart Vision Pro version provides a more comprehensive visual analysis for R&D applications.

- Time-saving on Quality Control

- Representative sampling, reliable results

- Improved process stability

IRIS Smart Vision – Fast & Easy Quality Control

- Define Your Quality Standards

- Measure Your Products

- Monitor Long-term Quality

Applications

Visual inspection and product batch validation

- Validation of suppliers’ raw materials quality

- Quality control of production

Process monitoring based on product color

- Check products quality at the end of the manufacturing process to avoid any drift

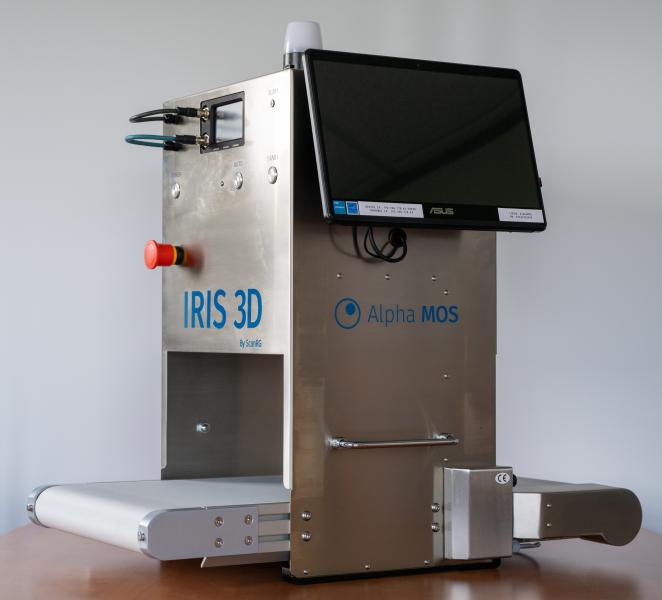

IRIS 3D Visual Inspection Analyzer

Based on patented multispectral 3D scanner technology, the new IRIS 3D by ScanRG is specifically designed for quality control applications.

Based on patented multispectral 3D scanner technology, the new IRIS 3D by ScanRG is specifically designed for quality control applications.

Innovation in visual inspection

- Powerful: complete product characterization in 3D (height, area, volume, and more) and color (RGB and NIR)

- Robust and precise: stable colors by active LED illumination, sunlight resistant, precise 3D data by laser triangulation method

- Fast: sampling rate up to 1,500 Hz

-

Cost-efficient: integration of 3D, color and data processing in one device reduces testing complexity and costs.

Main specifications

- Measurement of product visual parameters on a conveyor using multispectral camera

- Calculation of parameters such as dimensions, volume, surface area, baking color, color indices and gloss

-

Permanent storage of parameters and product images visualization and analysis.

AlphaSoft,

Sensory Analysis Software

AlphaSoft software operates all Alpha MOS instruments:

- HERACLES electronic nose

- ASTREE electronic tongue

- IRIS electronic eye.

It allows to monitor instruments settings, define analysis methods and sequences, run analysis and perform data acquisition.

It also achieves the data processing of Alpha MOS instruments measurements, using different models based on the application:

- Qualitative models: comparison of several samples on overall odor/taste/visual aspect, samples classification based on a criterion, quality/conformity control, shelf life monitoring

- Quantitative models: prediction of measurable parameters such as a concentration or a sensory attribute intensity.

Data processing modules (statistics packages, AroChemBase) can also be used to compute data from other analytical instruments.

AlphaSoft anticipates maintenance needs and avoids losing time on lab activity.

Thanks to this unique software platform, it is possible to combine HERACLES, ASTREE and IRIS results to have an overall point of view of products sensory features.

APPLICATIONS

of the visual analyzer to measure colours and shapes

The applications of the electronic visual analyzer for products’ colour and shape evaluation are numerous in industry since the visual aspect of products is often the first sensory attribute perceived by consumers. Thus industrials frequently use visual inspection, in particular during new products development steps but also during production quality control.

Control the conformity of your products with the visual analyzer

Control the conformity of your products with the visual analyzer

The consumer chooses his products mainly according to their appearance and he expects that his favorite products have a consistent visual aspect. With objective and reliable measurements, the electronic visual analyzer helps control the colour and shape attributes during the visual inspection of the production:

- Visual inspection and visual conformity tests: visual control of the colours and their proportions, size distribution control in a batch, detection of visible defects

- Visual control and assessment of process impact on visual aspect

-

Stability of shelf life follow-up of colours, characterization of visual aspect changes over time.

The electronic visual analyzer at the service of your R&D

The sensory profile and particularly the visual aspect of products have a strong influence on consumers’ choice and preference. Thanks to its numerous applications, the electronic visual analyzer is a precious tool to support the conception of new products that meet consumers’ expectations:

The sensory profile and particularly the visual aspect of products have a strong influence on consumers’ choice and preference. Thanks to its numerous applications, the electronic visual analyzer is a precious tool to support the conception of new products that meet consumers’ expectations:

- Recipe optimization to obtain the desired visual aspect

- Re-development of product (retro-engineering) to change or improve its visual aspect: new ingredients, new recipe

- Benchmarking of competitive products based on their visual aspect (colours and shapes)

- Change of manufacturing process and measurement of the impact on product visual aspect

- Correlation of the instrumental measurements of the electronic eye with consumers’ preference to support new product development.